If you want to buy groundnut oil milling machine locally in Nigeria, Lucky for you, I have a good new to tell you. Last year, Doing Holdings - Henan Glory Company has set up branch and overseas warehouse in Lagos, so you can buy groundnut oil milling machine directly in our branch.

Advantages of buying groundnut oil milling machine from our Nigerian Branch

1. You can go there to visit and see the machine in person, then buy groundnut oil milling machine directly in local, no longer need to wait.

2. Our engineers there can provide you with timely and efficient after-sales service.

3. If you want to set up a large scale groundnut oil production business, you can communicate face-to-face with our overseas manager, who can help you better understand the project solution, and can solve your problems, such as plant designing, technology communication, installation guide, etc.

The introduction of our Doing Holdings Co., Ltd. - Henan Glory Oils & Fats Engineering Co., Ltd.

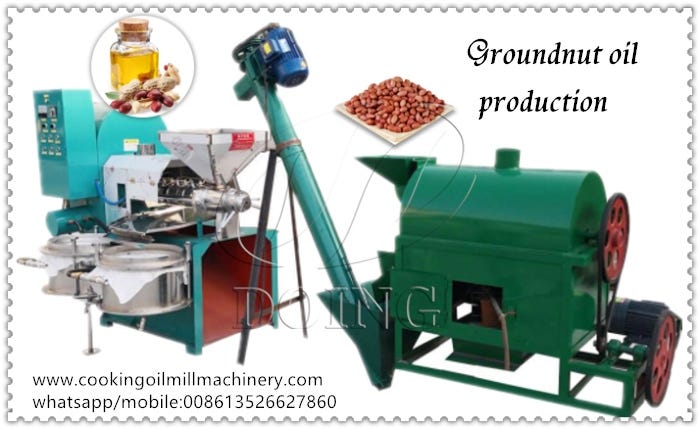

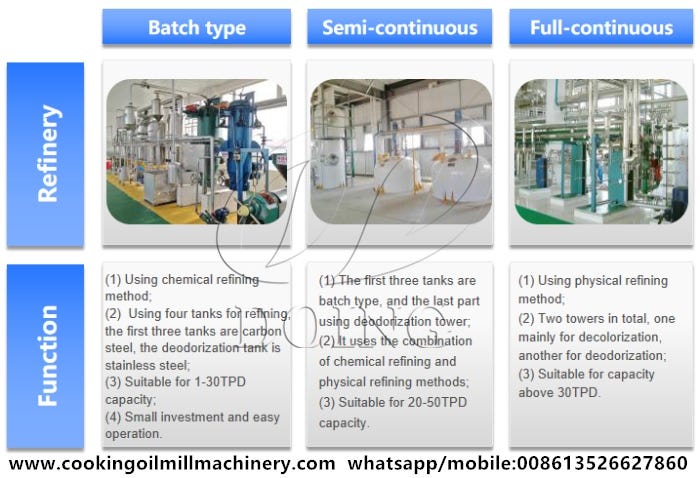

The company's main business ranges: various oil pretreatment, pressing, solvent extraction, refining, fractionation, winterization dewaxing equipment, storage, packaging, oil storage tanks, laboratory equipment and other complete processing lines; series of oil expeller, cooker, and filter, etc.

Welcome you to contact us!

http://www.doingoilmachine.com

whatsapp/wechat/mobile:008613526627860

Email: oilmachine@doingoilmachine.com