If you want to refine crude soybean oil, you need a set of soybean oil refinery machine. As the professional edible oil refinery machine manufacturer, Henan Glory Company can design different kinds of soybean oil refinery machine for you. Next, I will introduce the soybean oil refinery machine for you in details, in order that you can choose suitable machines for your soybean oil refinery plant.

1. The kind of soybean oil refinery machine

Based on the daily processing capacity, the soybean oil refinery machine can be divided into 1-2tpd mini soybean oil refinery machine, 5tpd, 10tpd, 20tpd, 30tpd, small scale soybean oil refinery machine, 50tpd, 100tpd medium scale soybean oil refinery machine and 100tpd-1000tpd large scale soybean oil refinery machine.

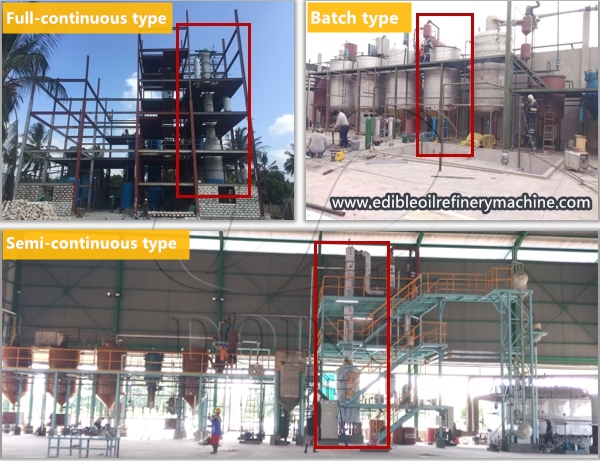

Different kinds of soybean oil refinery machine

Different kinds of soybean oil refinery machine

According to the degree of work continuity, the soybean oil refinery machine has three types: batch type soybean oil refinery machine, semi-continuous type soybean oil refinery machine and full-continuous type soybean oil refinery machine.

Besides, using different method of deacidification, the soybean oil refinery machine is also different. There is soybean oil physical refinery machine and soybean oil chemical refinery machine.

So you can talk your requirement with our sales, and the engineer will design suitable soybean oil refinery machine kind for you.

2. The refining process of crude soybean oil

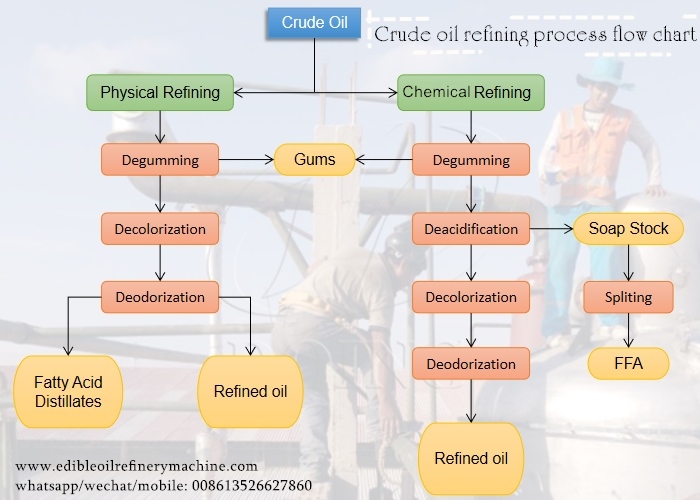

How to refine crude soybean oil with the soybean oil refinery machine? The refining process of crude soybean oil includes four processes: degumming, deacidification, decolorization and deodorization.

Soybean oil refinery process flow chart

Soybean oil refinery process flow chart

First, because there is lots of colloidal impurities in crude soybean oil, soybean oil degumming adopts hydrated degumming method. Add some hot water to make colloidal impurities dissolve in water. Then the batch type soybean oil refinery machine need to settle the impurities for a long time to separate the impurities from oil, but the continuous type soybean oil refinery machine uses centrifugal machine to remove the impurities.

Second, different deacidification methods need different equipment. Generally, batch type soybean oil refinery machine uses chemical deacidification method, which only need the refining tank. But semi-continuous and full-continuous soybean oil refinery machine adopts physical deacidification method, which need deacidification & deodorization tower.

Third, the decolorization method is using bleaching earth to absorb the pigments. But pay attention to that the decolorization process need vacuum condition. Then use leaf-filter to filter the waste white clay from oil.

Finally, the deodorization process also need vacuum condition, using distillation method to make the odors out. It deserves to be mentioned is that semi-continuous and full-continuous soybean oil refinery machine use deodorization tower, which cost more.

Only if contain four processes, it is the complete soybean oil refinery process. So if you buy the soybean oil refinery machine, you must discuss the soybean oil refinery process with the engineer. The complete soybean oil refinery process can make sure the quality of refined soybean oil.

3. The raw materials of soybean oil refinery machine

The deodorization tank or tower of soybean oil refinery machine

The deodorization tank or tower of soybean oil refinery machine

As edible oil refinery machine manufacturer, Henan Glory Company want to remind you that the deodorization tank or tower must use stainless steel. Because the temperature of deodorization process is very high, if use carbon steel for a long time, it maybe leak, which will increase the maintaining cost. So if you buy the soybean oil refinery machine, ask the raw materials of soybean oil refinery machine.

All in all, a set of soybean oil refinery machine can refine the crude soybean oil into refined soybean oil. However, you need buy high quality soybean oil refinery machine, which will avoid some matters in production process later. If you need, welcome to contact us, Henan Glory Company!

WhatsApp/wechat/Mobile:

008613526627860

E-mail: sales@doingoilmachine.com

https://www.edibleoilrefinerymachine.com