How much is the cost of cooking oil extraction machine to set up a small scale business?

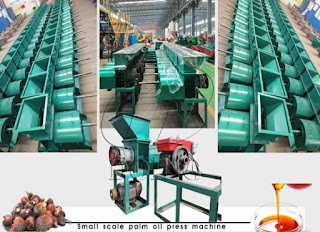

To set up a small scale cooking oil processing business, you should choose to buy cooking oil extraction machine based on your processing capacity of raw materials. So the cost of cooking oil extraction machine you need will be different. Henan Glory Company has three plans of buying cooking oil extraction machine for you. Please continue reading.

1. Processing capacity 1.3-3 tons per day -- single screw cooking oil presser

If your processing capacity is 1.3-3 tons per day, we recommend you our single screw cooking oil presser, which consists of five parts: hopper, gearbox, press chamber, pressing screw and machine frame. The pressing screw is the key to the entire single screw cooking oil presser, the choice of whose raw material will affect the quality and service life of the single screw cooking oil presser. Therefore, when you purchase a single screw cooking oil presser, you should pay attention to it.

The cost of buying a single screw cooking oil presser you need is about $1050-$1500, which may be different according to the different processing capacity. If you want specific cost quotation, welcom to contact us!

2. Processing capacity 3-11 tons per day -- automatic temperature controlled oil press machine

If your processing capacity is 3-11 tons per day, our automatic temperature controlled oil press machine is suitable for you. It can process 3-11 tons raw materials per day, which is widely used in different edible oil processing plants. Automatic temperature controlled oil press machine uses an electric heating coil device to heat the press, and make the oil press machine pre-heated quickly and start the production quickly.

If you want to buy the automatic temperature controlled oil press machine, you need about $1650-$3700. Although its cost will be higher, it worth that. If you want to expand cooking oil production scale later, it can be connected with other machine to form a complete cooking oil production line.

3. Higher production efficiency -- Simple cooking oil production line

If you want a more comprehensive cooking oil production line for your small scale cooking oil processing business, there is a simple cooking oil production line, which is made of three sets of equipment: cooking oil presser, cooker and oil filter.(Recommend reading: 1-30 tons per day cooking oil production machine working video)

The cost of this plan is at $6000-$15000. Cooker will help you regulate the temperature and moisture of your raw materials. Oil filter can filter impurities in your crude cooking oil, improving the quality of cooking oil. This simple cooking oil production line is very popular among small investors.

Above is the three plans and their cost scope we provide for you, and I hope it can help you make the right choice. Besides, our Henan Glory Oils & Fats Engineering Co.,Ltd also provides medium or large scale cooking oil extraction machine, palm oil processing machine, crude cooking oil refining, dewaxing or fractionation machine, etc. If need, welcom to contact us directly.

_%E5%89%AF%E6%9C%AC.jpg)