Soybean is the main oil seeds in the world, which solves many people’s requirement of cooking oil, it’s the second biggest oil seeds below the palm. Besides, the cake after producing the soybean oil can be used to make animal feed.

There are two methods to extract the soybean oil: pressing method and solvent extraction method, the best soybean oil method to making animal feed is solvent extraction. Solvent extraction is using the solvent to extract the oil from soybean. Both of pressing and solvent extraction need the pre-treatment.

Pretreatment includes:

Cleaning: clean the impurities of the soybean, such as stone, sand and other metal impurities, which will avoid the broking of the pressing machine by stone

Crushing: crush the soybean into small sections, which will make the flowing processing easy and increase the oil yield.

Flaking: flake the crushed soybean into the pieces by flaking machine, which will break the structure of the soybean to increase the oil yield.

Cooking: it is used to adjust the temperature and moisture of the soybean, which will make the solvent extraction reach the best conditions.

Soybean oil pretreatment equipment

Solvent extraction:

After pre-treatment, the soybean cake will be transported into the solvent machine, which includes four parts of solvent, DTDC .

The features of solvent extraction is the residual oil ratio is less than 1% in the cake, which is the best conditions to make the animal feed.

By this way, not only you can get more soybean oil, but also can make the best quality animal feed.

If you are interested in building the soybean oil processing plant, we are pleased to supply more technology information for you.

Contact us for free:

WhatsApp/wechat/Mobile:

008613526627860

E-mail: sales@doingoilmachine.com

http://www.cookingoilmillmachinery.com

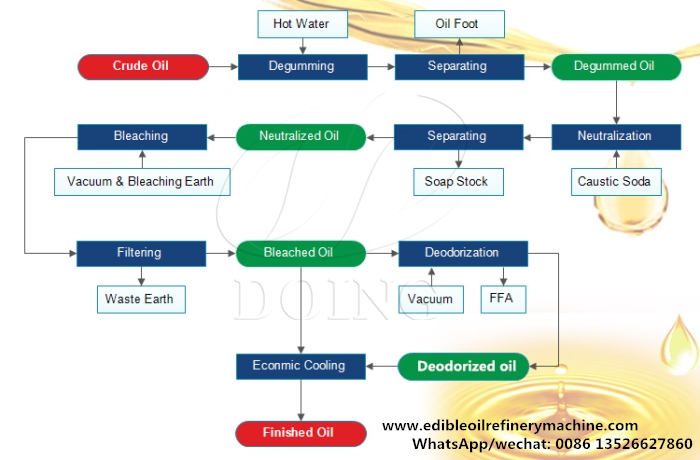

Sunflower cooking oil purification process

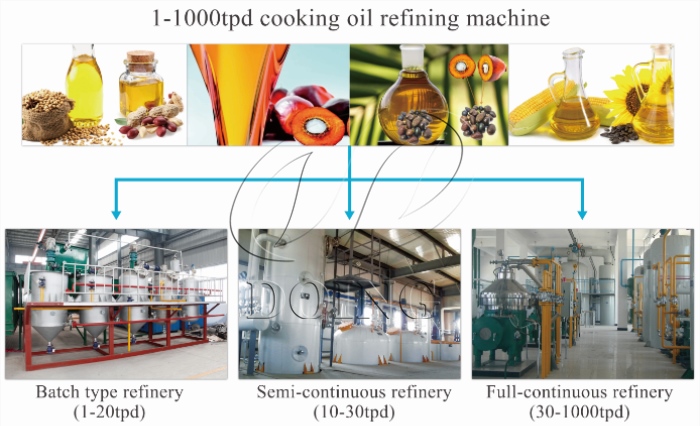

Sunflower cooking oil purification process Three different types of sunflower oil purication equipment

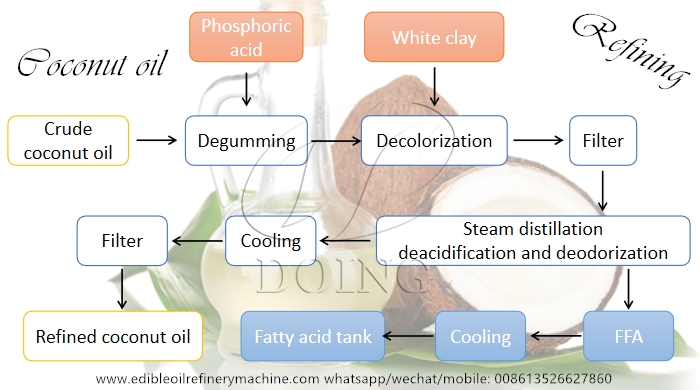

Three different types of sunflower oil purication equipment Coconut refining step

Coconut refining step_%E5%89%AF%E6%9C%AC.jpg)