Henan Doing Mechanical Equipment Co., ltd is one of the leading

manufacturer of palm oil processing equipment in China. We can provide

equipment with different capacities according to your needs range from

single machine to complete palm oil processing line. We are expert in

palm oil processing machine, palm kernel oil processing machine, palm

oil/palm kernel oil refinery line, etc. Our product has been sold to

over 80 countries around the world. And every year, we install many palm

oil mill plant project around the world, including small scale, medium

scale, large scale.

Palm oil processing business plan

Palm oil processing business plan

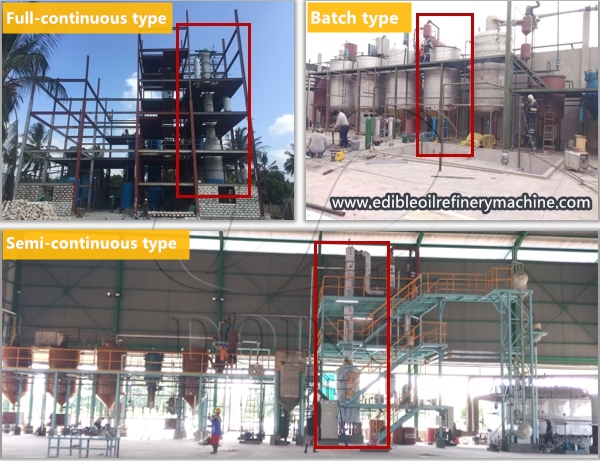

In all the best-selling equipment, the small scale palm oil refinery

plant is one of the highest order rate palm oil machine. Compared to

large type palm oil refinery plant, small scale palm oil refinery plant

boasts many favorable features that appeal to customers most in the

global market.Now let’s learn about the outstanding features of small

scale palm oil refinery plant.

1. Save Investment Cost: It is relatively cheap but

has the full functions of palm oil refining process. In most case, the

steam generator is applied in this small scale palm oil refinery plant,

so there is unnecessary to buy steam boiler.

2. Save Space or Land: No need of special workshop. It only needs about 9 square meters to put all the equipment

3. Simple Operation: It is fairly easy to operate the

whole set of scale scale palm oil refinery plant when the electric,

water and other indispensable materials are well prepared.

4. Extensive Use: It can be used to process a variety

of crude oils, such as soybean oil, sunflower oil, peanut oil,

cottonseed oil, coconut oil, rapeseed oil, corn germ oil, rice bran oil,

palm oil, palm kernel oil, etc.

Small scale palm oil refinery plant

Small scale palm oil refinery plant

What is the refining process of small scale palm oil refinery plant?

After understanding the features of small scale palm oil refinery

plant, what is the processing technology of the small scale palm oil

refinery plant?

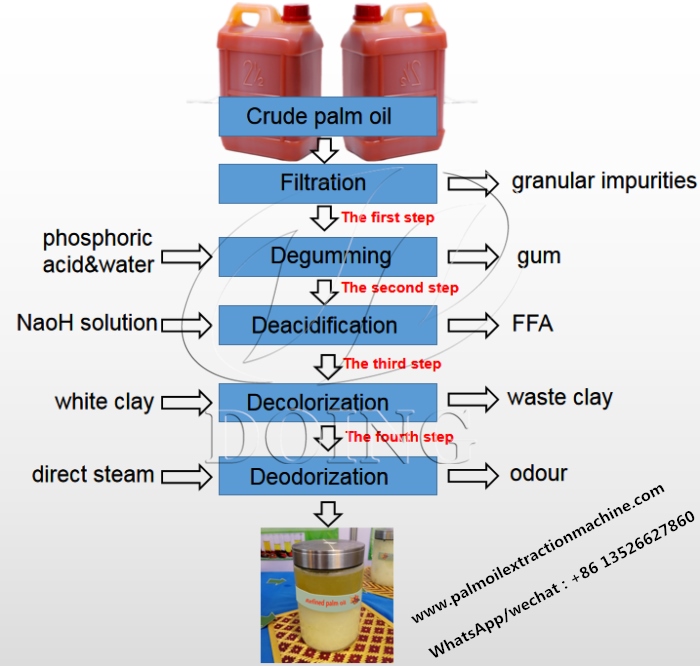

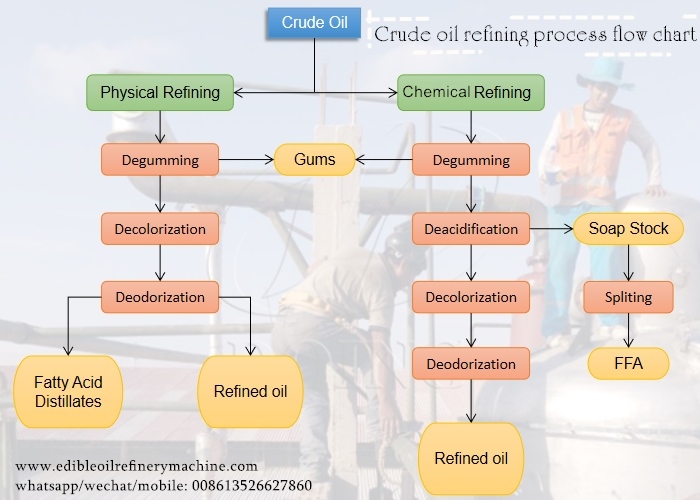

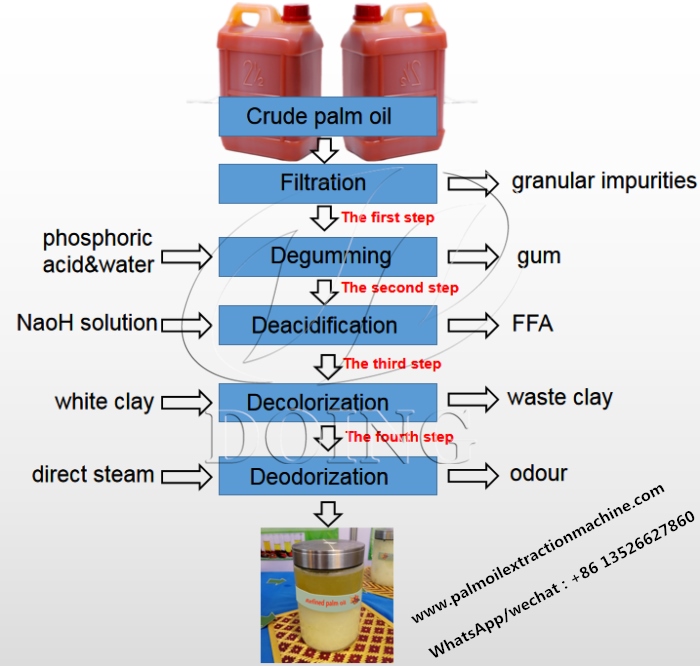

About the small scale palm oil refinery plant, it includes four mainly

sections:degumming, deacidification, decoloration, deodorization.

From crude palm oil to edible oil refining process

From crude palm oil to edible oil refining process

Step 1—Degumming section:

Usually, there are some phospholipid, gum, and protein in crude edible

oil. These impurities can be dissolved into oil when there is no water,

but once there is water in oil, these impurities can be dissolved into

water. So, in degumming section, we use the hot water to wash crude oil

for two-three times to make gold phospholipid condenses and reduces

colloid, and then remove these impurity.

Step 2—Deacidification section:

During this section, the most widely used method is adding some

chemical materials (alkali liquor) to remove the acid materials. And

then open the below valve release the soapstock.

Please Note: If the content of FFA in crude oil is

high, we will lost much oil and get much soapstock. But if the content

of FFA in crude palm oil is low, we will get more oil and less

soapstock.

Step 3—Decolorization section:

To make the color of the cooking oil transparent, we usually use White

Clay to odsorb the colouring components and to decompose hydroperoxides.

This step usually needs 25mins, temperature requirements around 105-110

Celsius.

Step 4—Deodorization section:

This step have high temperature requirement , around 260 Celsius. Based

on very high temperature, we can use steam to get off oxidation number,

aldehydes, and ketones in crude oil. In addition, some of acid and bad

smell also can be taken off in this step.

What is the price of small scale palm oil refinery plant?

After knowing the refining process and advantages of small scale palm

oil refinery plant, some people may want to know what is the price of

small scale palm oil refinery plant? Next, let's take a look.

As a professional manufacturer of palm oil refining machine, Henan

Glory Company can responsibly tell you that the exact cost of the palm

oil refining machine is decided by various aspects, including processing

capacity, requirement for final produced oil, local market, refining

technology, etc. The price range for small scale palm oil refinery plant

is usually $20,000~$12 ,000. For more specific cost, please directly

contact us. Our professional engineers and sales will takes all your

requirements into consideration and offer you custom edible oil refining

machine and corresponding cost.

Related reading: How much does it cost to build a palm oil refinery plant?

What are the palm oil refinery plant projects that Henan Glory company has done?

Before starting the palm oil refining business, some investors may also

want to know What are the palm oil refinery plant projects that Henan

Glory company has done? Please continue to reading, you will have a

deeper understanding.

Every year, we will export and set up many palm oil refinery plant

projects in different countries, including Indonesia, Liberia, Malaysia,

Ghana, Zambia, Peru, Jamaica, Congo, Tanzania, Zimbabwe,Togo, Mexico,

etc. Here listed some of our latest projects of edible oil refinery

plant projects for your reference. If you want to get the customized

design and detailed palm oil refinery project report, contact us

directly!

► 20TPD olive oil refinery plant in Peru

► 5TPD palm oil refinery plant in Indonesia

► 2TPD palm oil refinery plant in Liberia

► 5TPD palm oil refinery plant in Nigeria

► 30TPD soybean oil refinery plant in Zambia

► 100TPD palm oil refinery plant in Kenya

Different capacity palm oil refinery plant project that Henan Glory Company have installed

Different capacity palm oil refinery plant project that Henan Glory Company have installed

Please Note: It is just a little part of our projects

since it is too many to list here. If you can't find the related project

in your regions, please contact us to make sure whether we have built

up projects in your country.

Palm oil refining, the most important section of a complete palm oil

production line, can't be ignored. Small scale palm oil refinery plant

is the best choice for small or medium scale palm oil mill plant to

improve the oil quality and reduce the oil production cost. If you are

planning to enter the palm oil refining industry and want to know more

information about palm oil refining machine. Here, Henan Glory Company

will help you gain the complete knowledge, including its functions,

working principles, production process, setup cost, machines required

and more. Welcome to contact us.

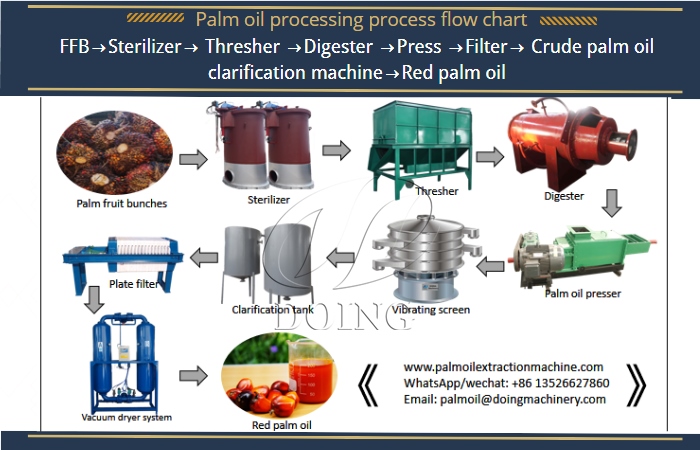

Palm oil processing process

Palm oil processing process Double screw palm oil press machine

Double screw palm oil press machine Simple type palm oil processing machine

Simple type palm oil processing machine Small scale palm oil processing machine

Small scale palm oil processing machine Different kinds of soybean oil refinery machine

Different kinds of soybean oil refinery machine Soybean oil refinery process flow chart

Soybean oil refinery process flow chart The deodorization tank or tower of soybean oil refinery machine

The deodorization tank or tower of soybean oil refinery machine

Palm oil processing business plan

Palm oil processing business plan Small scale palm oil refinery plant

Small scale palm oil refinery plant From crude palm oil to edible oil refining process

From crude palm oil to edible oil refining process

_%E5%89%AF%E6%9C%AC.jpg)